#Walking Beam Furnace Water Sealing Groove Water Seal System

Description

Basic Info.

| Model NO. | Water Sealing Groove |

| Usage | Provide a Sealed Environment for Furnace |

| Delivery Date | Refer to The Contract |

| Type | W Type/V Type |

| Transport Package | Frame Packaging, Woodencase Packaging, etc. |

| Specification | Customized |

| Trademark | PRIME |

| Origin | China |

| HS Code | 8417100000 |

| Production Capacity | 1000 Sets/Year |

Packaging & Delivery

Package Size 100.00cm * 50.00cm * 100.00cm Package Gross Weight 25.000kgProduct Description

Product DescriptionWalking Beam Furnace Product Description

1. INTRODUCTION2. GENERAL GUIDING PRINCIPLES AND TECHNICAL STRATEGYThe proposed furnace should meet the requirement of high productivity, high quality and low energy consumption. The control for hydraulic, electrical, instrumentation and automation should be safe, reliable and economic. The equipment should meet production requirement when in operation and should conform to the specification of the tender documents. It should also consider rolling capacity expansion in the future. 2.1 GENERAL REQUIREMENT AND SOLUTION TO COMBUSTION SYSTEM • The walking beam type furnace is divided into three zones: preheating zone, heating zone and soaking zone, to meet the heating requirement. the discharged billets should meet rolling requirement in terms of temperature and temperature difference. .• Lower part of the heating zone Ι, heating zone ΙΙ and soaking zone all have side burner with big adjusting ratio and low NOx, while the upper part of heating zone Ι, heating zone ΙΙ and soaking zone all have flat flame burner.--The side burners will have adjustable flame to ensure the temperature uniformity in the furnace width direction.--The flat flame burners are adopted on the upper part because of lower hearth. There will be uniform temperature radiant surface formed to ensure quick heating to the furnace hearth and good heating quality to the slabs. The flames will not flushing the refractory directly and results lower scale loss.

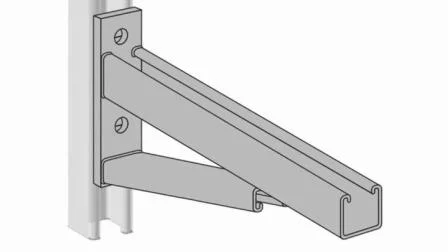

• The burner design should ensure sufficient mixing of air and mixed gas, to reach optimal ratio and accurately control the air inside furnace.2.2 TECHNICAL STRATEGY FOR HEATING CAPACITE• The designed capacity should consider certain potential, to meet future higher capacity when rolling bigger size products. This offer is designed based on 300t/h (hot charging) and considers a 20% surplus for future expansion.• The piping for air and gas should have a certain surplus. The fan should have a higher capacity.2.3 TECHNICAL STRATEGY FOR HEATING QUALITY• Heat recovery section is arranged to recover residual heat of flue gas to preheat the billet, hence saving energy consumption.• The atmosphere inside the furnace will be strictly controlled through an automatic control system to achieve minimum oxidization.• The heating zone and soaking zone should be designed with a considerable adjusting range to meet the different heating requirements under various capacity production.• The water beam is designed with an optimal arrangement. The skid block should have a good design to ensure fewer skid marks.• The discharging is by the extractor. The walking beam mechanism moves softly and places the billet slightly to avoid scratches on the billet surface. When the furnace requires a relatively long-time shutdown, the walking beam will be stopped at the same level as the fixed beam, or it can move forward to reduce billet deformation.• Advanced instruments and computer control systems are adopted to ensure accurate temperature control and prevent overheating to the billet.• Burners will be properly located and the zone length will be suitably divided to provide good heating distribution.2.4 ENERGY SAVING MEASURES• High efficient steel tube air preheater can preheat the combustion air to about 650ºC by recovering the heat of flue gas, thus reduce fuel consumption.• The working surface has castable integrated structure, the furnace top, hearth and side wall are compound structure. Refractory has high thermal resistance value and good performance refractory to reduce heat loss.• Big spacing supporting column and water piping longitudinal beam are adopted. The supporting beams and columns are well arranged to reduce surface area of water cooling piece. The supporting beam and column have refractory fiber blanket and high strength castable dual layer insulation. The cooling is water cooling.• The walking mechanism should consider the walking beam is moving at low speed while supporting and lowering the billet. The scale loss will be lower and the impact to the insulation layer of water cooling beam will be less.• The furnace door will be in optimal configuration. The structure will be designed with flexible opening and closing. The seal will be tight to reduce heat loss.2.5 FURNA HEARTH MECHANICAL,HYDRAULIC SYSTEM AND SCALE REMOVAL• The walking mechanism has a dual wheel inclining rail lifting type. The lifting frame and translation frame have a centering device to ensure minimum deviation in the furnace width direction. The mechanism is easy for adjusting, maintenance and operation. The foundation of the translation cylinder will be set separately on the furnace hearth. The lifting frame will have a mechanism to ensure synchronization.• Hydraulic driving is adopted. The hydraulic system has a stable start and stop and has little impact. The main pump and proportional valve are imported products. The hydraulic cylinder has distance sensor control. The design the component makes will fully consider the conditions of other furnaces for better replacement of spare parts.• Grease the lubrication systemDouble line lubrication is considered. The main equipment will be the Lincoln brand. • Scale cleaning systemThe water sealing part has a reliable dry scale removal device. The seal is detected by an electrical water level detector. The water seal trough has water level detecting points.The discharging side and soaking zone hearth area have a scale hopper for online scale discharging. It can also clean the scale when the furnace is in maintenance.There will be a scale chute between discharging door and discharging table for cleaning the scale fell at discharging. The scale will be discharged to scale flushing trough.Both sides of the soaking zone have scale cleaning door for online and offline scale cleaning.2.6 ELECTRICAL CONTROL AND AUTOMATIONAdvanced and reliable electrical control and instrumentation equipment are adopted. The basic automation and process automation are detailed and improved to realize operation automation and material tracking.-- automation control system• The detecting points of temperature, pressure and flow are designed to meet control requirements and each control circuit can meet the normal production requirement for the reheating furnace.• Safety protection system and various breakdown indications, alarms, and quick cut-off control are available for the system.• Furnace pressure and temperature auto control can be realized.-- sequence control system• PLC system is adopted for sequence control to realize full line tracking control from reheating area to billet discharging.• PLC monitoring image: the reheating furnace area working conditions, various breakdown indications, and furnace area equipment view will be monitored.• The electrical and instruments should have interconnection and reserves interface with the outside transmission.--Level 2 automationThe Level 2 automation control mainly includes the tracking of billet position, identification, temperature calculation, dynamic temperature setting, coordination with rolling pace, decision making for ready for rolling, the record of production status and reporting, etc.3. DESIGN CONDITIONS AND BASIC TECHNICAL PARAMETERS3.1 FURNACE TYPEA walking beam reheating furnace is used for reheating the slab with the fuel of mixed gas;Walking beam mechanism: Two wheels on slope rail, hydraulic drive;Charging /discharging mode: charging with the pusher at the charging side, discharging with the extractor at discharging side;Slab to be charged into the furnace from both directions i.e. from the left as well as from the right side. Sensors etc. for the measurement of slabs shall be provided accordingly.3.2 STEEL GRADES FOR HEATINGMaterial of Slab Low and medium carbon steel and low alloy steel.3.3 BILLET SIZEConcast Route; Slabbing Mill Route; Thickness (mm): 200/225/250, 180-250; Width (mm) : 950-1830, 750-1850; Length (mm): 9000-10500, 4500-5250 & 7500-10500; Ref. Slab size 210x1280x10250mm; Slab weight: 33T (max); 3.4 CHARGING AND DISCHARGING TEMPERATURESlab charge temperature: Ambient i.e. cold charged.Slab discharge temperature:~1250ºC. 3.5 SPECIFIC CONSUMPTION:Average fuel consumption of 0.3 MKcal/ton (with cold charging of slabs) of slab rolled on regular basis and with scale loss of max 0.6%; 3.6 HEATING QUALITYTemp. diff. between the surface and core of the discharged slab 30ºC max. (For all points of the slab);3.7 FUELFuel to be used mixed gas of CV1650±50 to 2300 kcal/m3;3.8 FURNACE CAPACITYRated output is 300t/h(with mixed gas of CV 2300kcal/Nm3;cold charging, room temperature,210 mmx1280mm x 10250mm,common carbon steel, discharging temperature 1250ºC);Rated output is 260t/h(with mixed gas of CV 1650kcal/Nm3;cold charging, room temperature,210 mmx1280mm x 10250mm,common carbon steel, discharging temperature 1250ºC);3.9 CONTROL LEVEL OF FURNACESequence control system: the production process that the conveyance of slab from charging roll table to discharging roll table and transferring the slab before the rolling mill can realize the computer automatic control;Combustion control system: the computer system which can realize the automation control for furnace temperature and furnace pressure;Level 2 automation:The main task is based on production process on the heating requirement to heat the billet inside furnace. Through optimal setting and calculation of mathematic model, each zone temperature and fuel flow will be controlled to have direct control on the heating quality. 3.10 COOLING MODECooling system Skid & support Pipes: Non-Evaporative Cooling with industrial water.Other parts of the furnace: Ordinary water cooling.3.11 ENERGY MEDIUM

1) Fuel:――mixed gas:Fuel to be used Mixed gas of CV1650±50 to 2300 kcal/m3;1650±50 to 2300 kcal/m3;Flow rate of T.O.P: 47000m3/h(cold charging 300t/h, CV 2300 kcal/m3, skid well wrapped, 20% surplus is considered)Flow rate of T.O.P: 56750m3/h(cold charging 260t/h, CV1600 kcal/m3, skid well wrapped, 20% surplus is considered)Pressure of T.O.P: 8000~10000Pa2) Water cooling system--Turbid recirculating cooling waterUsage: for water seal troughsSupply pressure: 0.3 MPaQuality of water: turbid circular cooling waterFlow: normally 60m3/h--Purified recirculating cooling waterUsage: for skids, pillars, roller tables, blowers, industrial TV, hydraulic systems, etc.The highest temperature in summer: ≤35 ºC Increase of temperature: 12~15 ºC(normally) The highest temperature of outlet: 55 ºC Requirements for water qualitySupply pressure: 0.4~0.5(≥return water pressure+0.2)Flow: 600m3/h (normally)--Emergency waterUsage:When purified recirculating water is in trouble, emergency water is switched on for use. The requirements for the quality of emergency water is the same with that of purified recirculating water. Flow: 300m3/h Supply pressure: 0.4~0.5(≥return water pressure+0.2)Supply temperature: ≤ 35 ºC Current water quality is indicated as below: 3) Compressed air source system ――nitrogen Usage: purging for gas pipeline Pressure: 0.4-0.5 MPa(≥return water pressure+0.2)Supply temperature: ≤ 35 ºC――nitrogen or compressed air used for instrumentationUsage:gas for instrumentation(industrial TV etc.)quantity: 1m3/minQuality of gas source: dust particle size of dry gas after purifying is less than 3μm, dust content is less than 1mg/m3Oil content of dry gas after purifying shall be less than 1mg/m3Dew point of dry gas after purifying is less than -22ºCWorking pressure of gas source:0.5MPa.4) power supplyThe existing HV system and substation shall be modified. The 415V power supply system shall be modified.The HV system power supply shall be connected to reheating furnace HV equipment, like fans.The LV power supply shall be connected to incoming cabinet of furnace proper MCC.The power load refer to motor list.

Company Profile

Vision

With decades of rapid development and accumulation, China has been perfect and mature on technology and management in various industrial areas, shaping a complete processing manufacturing industry with competitive price, well known for its excellent skill, high efficiency and hardworking team with qualification for personnel dispatching.

| ProfessionalProfessional technical and management team with abundant experience in the implementation of domestic and international projects; |

| ResponsiveResponsively and meticulously, translating your needs into complete solutions; |

| IntegrationIntegrating various technologies and resources in China and fulfilling complementary advantages, by relying on professional teams; |

| MotivationMotivated to provide the optimal solution and quality products; |

| ExceptionalExceptional, delivery and,implementation of projects to meet, your expectations; |

Our teamProfessional technical teamPrime is staffed with professional import & export team skilled with the practice of import and export business, including sea freight packing, logistics organization, L/C review, cargo booking, and customs clearance, L/C negotiation, double authentication of shipment documents, etc.All above personnel are well experienced in the execution of projects in Southeast Asia and Middle East. Complete procurement mechanismOur professional team of procurement offers strict management of supplier 's qualification inspection and selection, complete system of supplier listing, rating and elimination, to ensure the supplier is qualified and capable of implementing the project and supplied with product of high quality, and maintain a healthy and good condition of credibility, contract settlement and capital flow management.Quality management systemOur complete quality management system , the process control covering from Scheme formulation , engineering technology, detailed design, to processing and manufacturing of equipment and material , ex-factory test and site erection and commissioning till it put into production, which through multi-level inspection, tour inspection, supervision and node control can ensure quality of the final product.Well experiencedExecutive team is abundant in experience of overseas project implementation with similar project working experiences, esp. experience in Southeast Asia, Middle East projects;ISO System Certification

Partners

Our Contact